Production technology

Flour from the husk of oats is an analogue of wood flour and represents the small particles of the shell (husk) from the core of the oat grain of arbitrary shapes, obtained in the milling process.

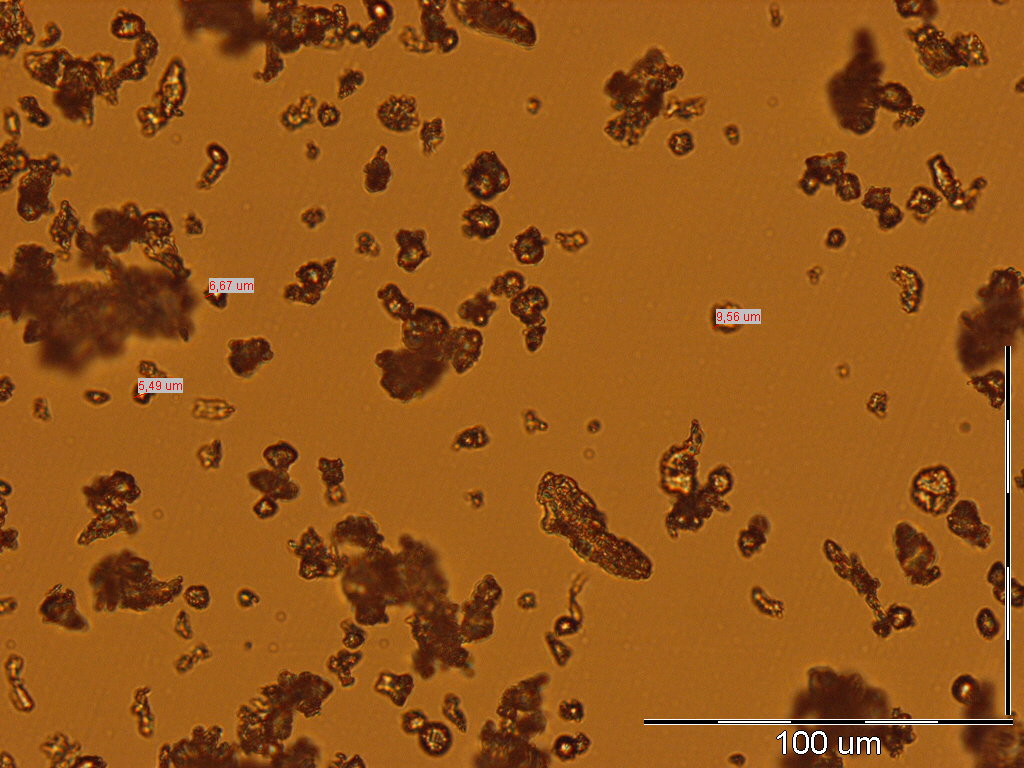

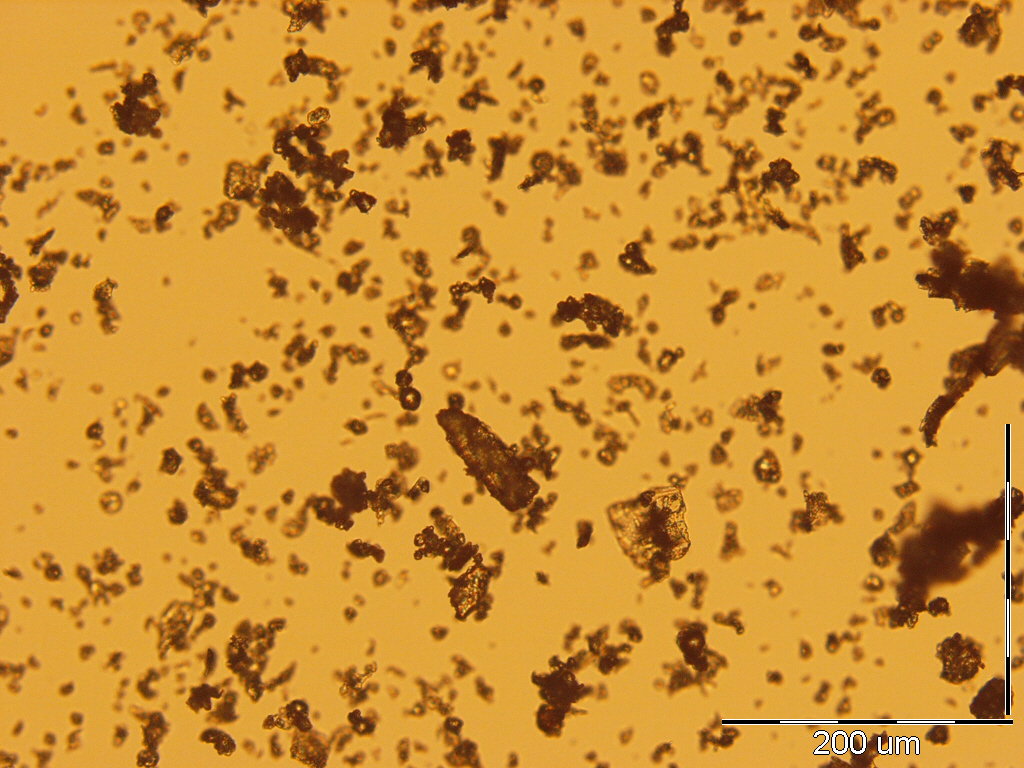

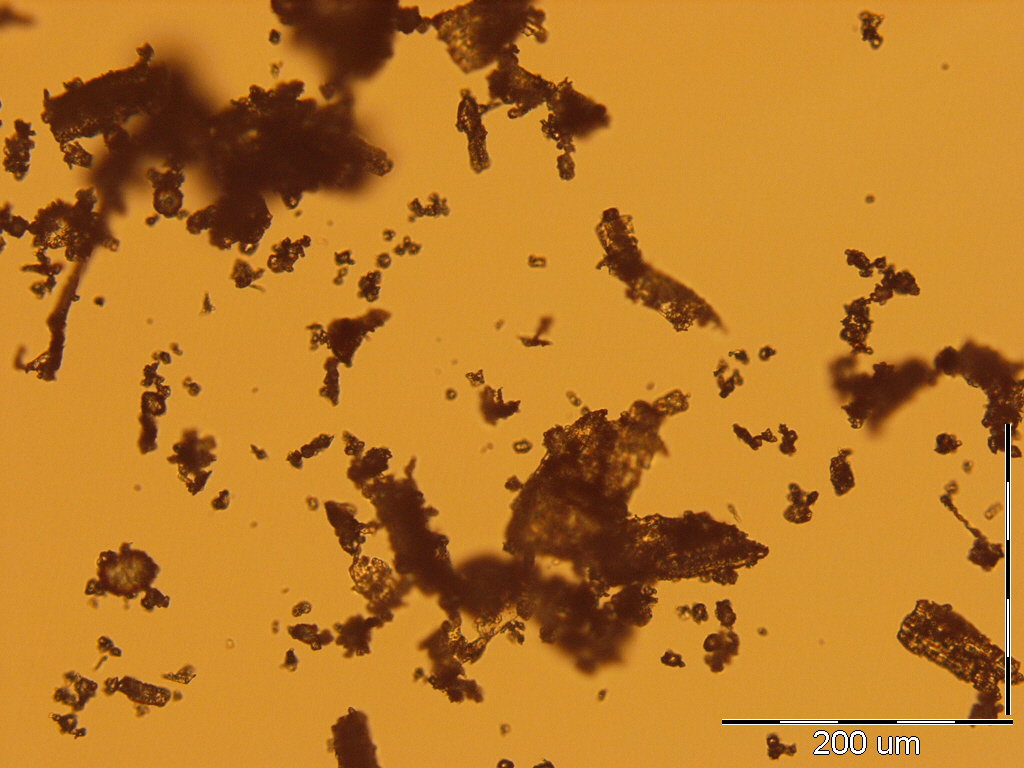

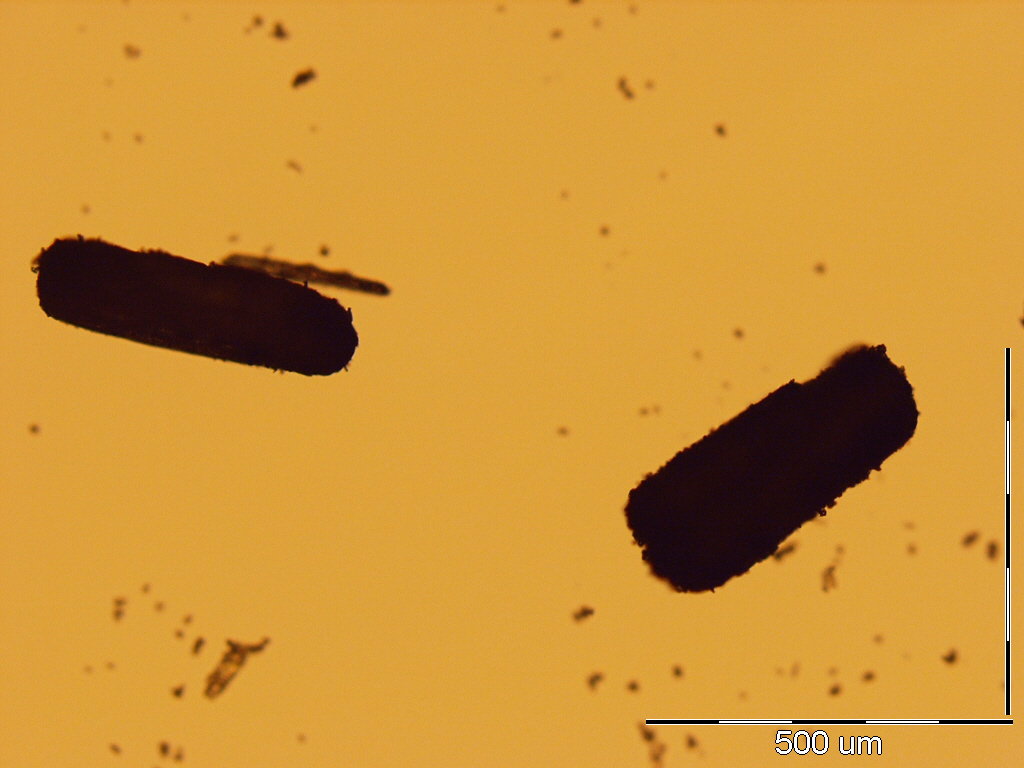

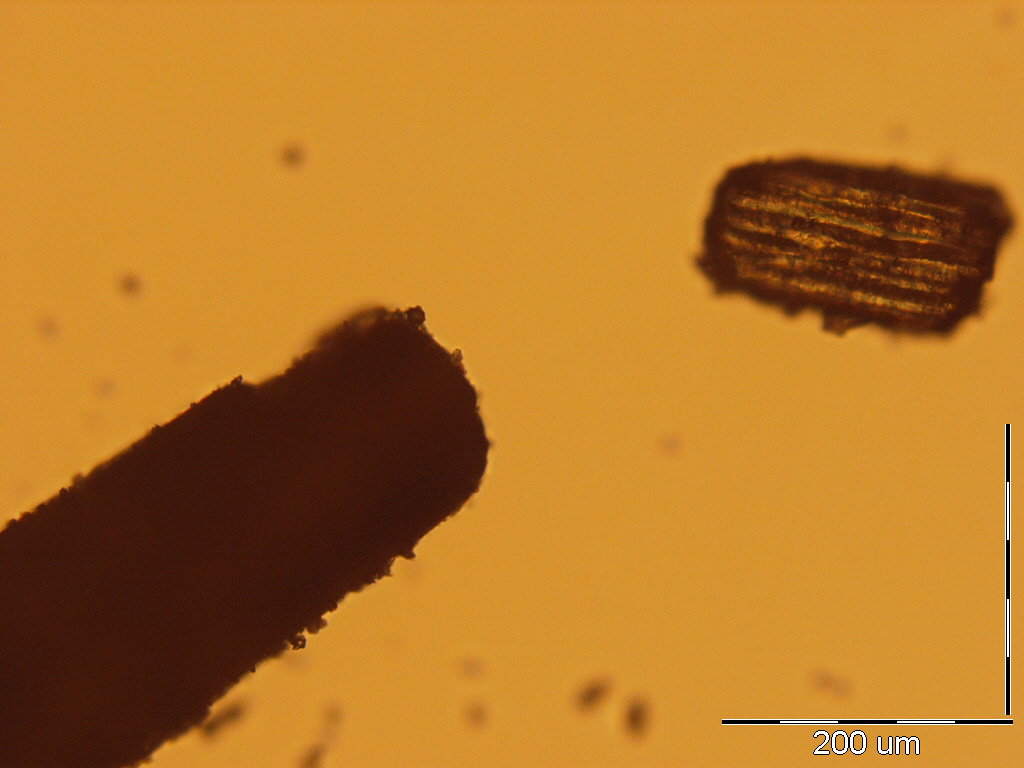

Flour production is carried out on equipment specially made for this purpose. For grinding the husks of oats, an ultra rotor mill of the original design is used. In the technology of flour production there is no pre-drying of raw materials, which eliminates the ingress of combustion products and various flour inclusions. In this case, the humidity does not exceed 4-7%. The resulting flour particles from oat hulls have random irregular shapes. On the one hand, this is due to the peculiar structure of oat hulls and a tendency to form fibrous particles during milling. On the other hand, during crushing, the particles as a result of random multilateral impacts are subjected to squeezing, striking, chopping, repeated impact, as well as friction, both between themselves and on the internal parts of the crusher.

The specific fractional composition of the flour depends on the milling and screening mode of the particles

Products are manufactured in accordance with TS 01.11.33-001-04058968-2017.

The following flour grades are distinguished: M120, M140, M160, M180, M200, M250, M400, M560 and micropowder.

Bulk density depends on the fraction of flour and ranges from 200 to 300 kg/cu.

Flour has pronounced sorption properties.

Refers to flammable, slow-burning materials, ignites in the air at temperatures above 250 deg. C.

The increased content of inorganic substances in the flour prevents the formation of explosive aerosol mixtures.

Flour from oat husks absorbs moisture, so it is packaged in polypropylene bags or in big bags with a polyethylene liner, placed on wooden pallets.